Department of Environment, Health and Natural Resources PCB Landfill – Warren County, North Carolina

The infamous Warren County PCB landfill is recognized as birthplace of the Environmental Justice movement and as having the single largest civil disobedience protest since the Civil Rights era. Over 500 citizens were placed in jail for protesting the land filling operations. The site was selected by the state, against the wishes of the community, as a CERCLA remedy to dispose of PCB tainted soil purposely discharged along 210 miles of road shoulders throughout North Carolina.

In 1982, feeling the tremendous pressure of the community, the Governor promised that the site would be detoxified (remediated) when technology to do so was available. Subsequently, in 1995, after $1 million was awarded to the community, the Joint Warren County State PCB Landfill Working Group retained Patrick A. Barnes, P.G. and Barnes, Ferland and Associates, Inc. as one of two science advisors. BFA assisted the community in a community led evaluation of detoxification feasibility and assessment of the overall integrity of the facility. BFA ensured that the needs of the community were met at every step in the process including job training and employment of area companies and local residents.

Over a seven-year period, BFA was responsible for the development and implementation of detailed environmental impact assessment for that PCB landfill as well as performing community outreach services. The facility which had been in existence for more than 15 years had never had a comprehensive evaluation performed. That evaluation assessed the hydrogeological setting and determined the best locations for environmental samples to accurately characterize the current integrity of the facility and to lay the groundwork for the remediation. During the assessment, hundreds of environmental samples were collected under the watch full eyes of the EPA, State and Community. BFA worked with all stakeholders particularly and the Joint State Warren County PCB Landfill Working Group.

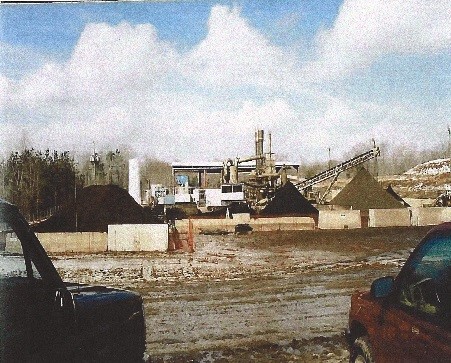

Subsequently BFA with MACTEC as a subcontractor was selected as the remedial design and community construction management contractor. The project was implemented with oversight from EPA Region IV. The selected remedy included state-of-the-art detoxification technology, such as Base Catalyzed Decomposition (BCD), and thermal desorption. BFA design was incorporated into a design-build criteria package and BFA provided construction oversight on behalf of the Community.

The remediation was concluded in 2003 by excavating and thermally desorbing then redisposing of over 60,000 tons of PCB impacted soil, at a cost of 13.6 million dollars. BFA and MACTEC developed all project work plans and the specifications necessary to successfully bid the site detoxification. The work plans included as part of the design were: Final Detoxification Design; Community Outreach and Involvement; Health and Safety; Emergency Response; Site Operations Performance Demonstration; Construction Quality Assurance; Air Monitoring; Final Verification/Confirmation Sampling Design Plans and Specifications.